Transforming

the industry

Connovate supports the building industry in meeting its climate targets by reducing the cement volume in concrete, while maintaining the properties of the concrete.

We do this by introducing Connovate CemCut that replaces up to 50% of the cement volume in concrete.

The implementation of Connovate CemCut, to any concrete production facility is fast (2-4 months) and requires no investments.

Why Connovate

Tailored to meet climate targets

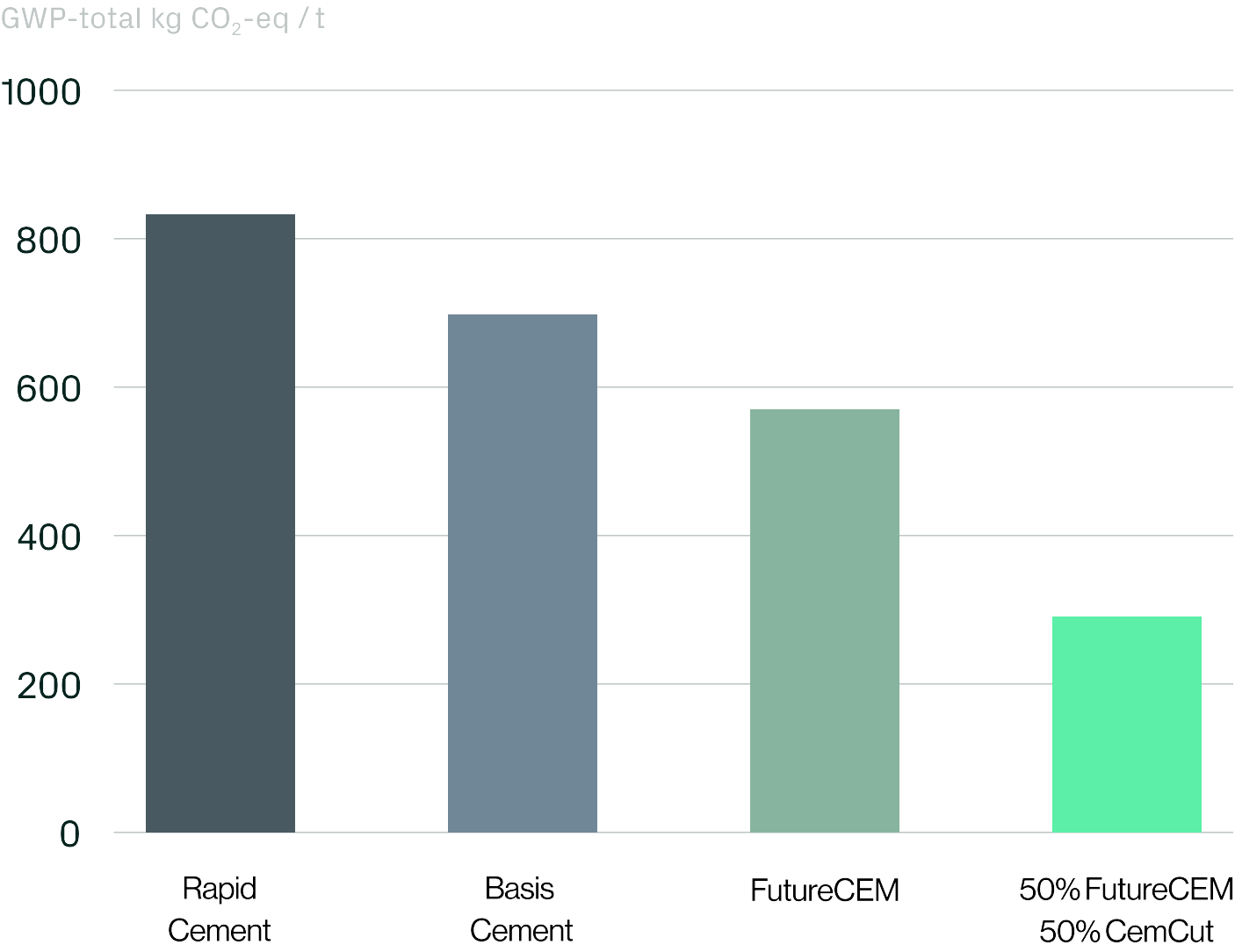

CO2 REDUCTION

Using CemCut in combination with a

reduced volume of cement Connovate

offers a very low CO2 emission.

Implementation

a simple process

How does it work

Who is Connovate

Rooted in

innovation

From the beginning our focus has been on the development of Connovate High Performance Concrete which has been sold to both Asia and Africa, where we also helped clients build concrete panel factories.

Based on many years of research and development within the area of High Performance Concrete we recently developed Connovate CemCut to support production of traditional concrete with strongly reduced CO2 emissions.

FAQ

Let us answer your questions

Empty

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

What are the ingredients in Connovate CemCut?

Connovate CemCut is a combination of materials already approved by the Danish Standard DS 206:2024. Requirement specifications are noted in Anneks P.